ISO

UPL is a certified logo holder of International Certifications (FTSE4GOOD, ISO 14001, Responsible Care, ISO 9000 and ISO 18001) for demonstrating strong environmental, social and governance practices.

91% of production from our manufacturing sites is certified under ISO14001 and ISO45001 standards.

Responsible Care Committed Company

Responsible Care is a global, voluntary initiative developed autonomously by the chemical industry for the benefit of the chemical industry. This initiative runs across 52 countries accounting for nearly 90% of the global chemical production. UPL is a recognized Responsible Care ompany, awarded the use of its logo. We voluntarily adopted the practice codes of the Responsible Care (RC) initiative accepted by Indian Chemical Manufacturers’ Association and implemented the ISO - 14000 (Environmental Management System), demonstrating our commitment towards continuous HSE performance improvement.

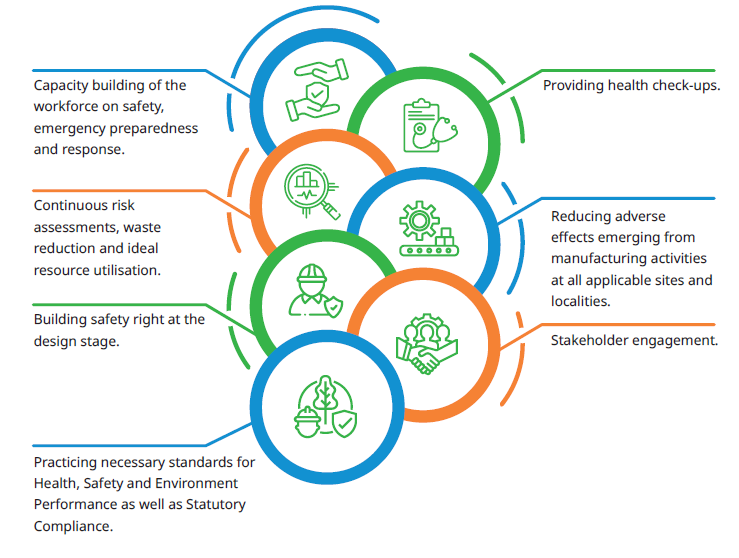

Safety Management & Practices at Manufacturing Sites

- HSE Issues are always given high priority at UPL.

- A committee of HSE Officers has to monitor Health, Safety and Environment Preparedness standards and practices.

- This is to ensure that our HSE management systems are world class and we achieve zero incidences at the work place. We realise that as a world leader in manufacturing, we need to put safety & health systems in place.

- We partnered with Dupont, Syngenta to evaluate HSE management systems across all manufacturing sites. This exercise was spread over three months and the evaluation study has opened up new avenues for improvement.

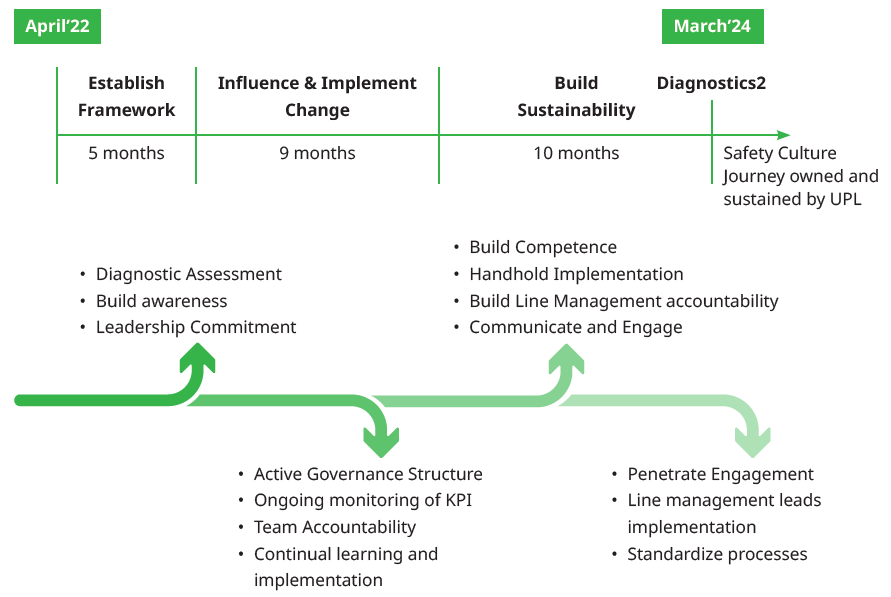

- Our aim is to graduate from the present dependent HSE culture to an interdependent culture.

- An inter-site benchmarking is done regularly to encourage healthy competition between sites.